Meet the Multifaceted Vacuum Chamber

One of the more versatile industrial tools, the vacuum chamber, is widely used in many fields. Essentially, it tests the vacuum effects on various materials, parts, assemblies by removing air and pressure. It’s a pretty simple concept yet incredibly effective.

One of the more versatile industrial tools, the vacuum chamber, is widely used in many fields. Essentially, it tests the vacuum effects on various materials, parts, assemblies by removing air and pressure. It’s a pretty simple concept yet incredibly effective.

They’re able to successfully imitate natural conditions with potential vacuum and give accurate testing results.

The use of the chamber, of course, depends on the industry in question. Some manufacturers employ it to test how stable their package is for long-distance traveling.

Other more specialized areas, such as the space industry, rely heavily on it to assess how well a specific part can endure cosmic vacuum and pressure. Visit https://www.sciencedirect.com/topics/earth-and-planetary-sciences/vacuum-chamber for more information.

Different Types

Vacuum chambers come in many different sizes. This isn’t meant to complicate your life unnecessarily, but they all serve different purposes, depending on the industry. The ones that test tiny parts are smaller, while others can take up an entire room (think outer space equipment, aircraft parts, etc.)

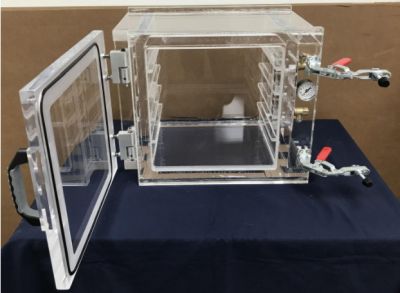

One standard type is known as the box vacuum chamber. This of one of the most versatile kinds you can find: professionals use it to do atmospheric tests, degassing, tribology, cosmic simulations, and some other applications. The use UHV, or ultra high-vacuum, meaning it can go as low as 100 nanopascals.

Since testers often use them in situations where pressure’s extreme, these rectangular chambers need to have very thick and braced walls to endure the unforgiving conditions.

Then, you have cylindrical chambers. People mainly use them to test helium leaks or to degas, and they can be vertical or horizontal. The main difference between the two is access: the former has to be lifted, while the latter can be entered from either way.

Yet another standard is the spherical chamber. It’s extremely convenient as it allows you to achieve multiple concentration points on the sample. As to use, professionals often perform UHV testing, laser deposition, surface testing, etc.

Industrial Application

Industrial Application

Vacuum chambers are genuinely invaluable to many industrial sectors. This is because they provide essential insight into a particular product, giving a load of important data, allowing the manufacturer to make the necessary adjustments and enhance the product’s quality and performance. Let’s check out some common applications of the vacuum chamber.

The industry that benefits the most from it is aerospace, where each product requires thorough testing before it’s put into use. You cannot use items such as various electrical components, switches, panels, seat cushions without prior testing in a vacuum situation. Otherwise, there might be safety and performance issues. Click here to learn more.

Another area that relies on this equipment is the chemical industry. Namely, the many different processes such as polyurethane production, distillation, degassing, and others need to keep chemicals under continuous pressure; otherwise, the products will be damaged and useless.

While we’re on the topic of damage and spoiling, we mustn’t forget about the food industry. Its primary concern is to test the boundaries of each product, especially those that require a certain temperature. Chambers can eliminate gases and moisture from potentially contaminated products and help with cooling, freezing, and drying, all essential processes for safe food transport.

Product safety is a highly sensitive issue in the biopharmaceutical industry. Thanks to vacuum chambers, companies can accurately determine the quality of each product, its deterioration point, shelf life, the influence of outside factors, etc. They assist during sterilizing, distilling, crystallizing of different medications.

High Versatility

Apart from the vacuum chamber’s ability to create an environment with no atmosphere or particles, it helps with a number of tests and operations. The space industry, for instance, would have a tough time ensuring the safety of astronauts without these instrumental pieces of equipment.

Moisture is a nightmare when it comes to products. Many materials are super-sensitive to dampness, and more often than not, the damage is irreversible. Luckily, chambers can remove moisture instantly. While some people use dehydration for the same purpose, vacuum is a superior process.

We already mentioned degassing a few times: it’s a process that, through lowering the pressure, eliminates gasses from a liquid. For example, metals often fall victim to gases that reduce their quality and performance, so removing the excess with a vacuum chamber is necessary.

Another handy application is coating or film deposition. It involves applying a very thin, protective layer, which can be atomic, sputtering, PVD, or some other type. This method is heavily used in the automotive and medical industries, semiconductor manufacturers, aerospace, etc.

The unique ability of a high-quality, stainless steel vacuum chamber to recreate atmospheric conditions is invaluable during product testing. It’s vital to ensure that a given item will not fail in deep water, at a high altitude, or even in space. The magic of these chambers is that you can adjust the exact height or depth at which the product will be used.

Fast Crystallization

In today’s fast-paced manufacturing, companies cannot wait for products to crystallize naturally. Therefore, using vacuum chambers can be a huge time-saver. Crystals are formed when you get solid deposits from a solution. Without the assistance of chambers, this would take ages and ages.

They eliminate these liquid solutions to create solid crystals, speeding up the entire process by a wide margin. Also, they do an excellent job with cooling products, removing moisture much more quickly than traditional methods, thereby extending the product’s shelf-life. For that reason, they’re the best option available on the market today.