How Many Types of Bending Are There?

This is a craft as old as the history of humanity. In ancient Greece, the art of bending iron was taught from father to son, and in some places, it almost became a religious ritual.

At first, they used only their hands to create the desired shape of tubing. When they found out that this approach required a lot of time and effort, they started to work with various tools and machines.

There are many types of tube benders. Their shape and size are not limited only by the imagination: from a simple manual hand tool for bending tubing to monster hydraulic presses weighing several tons.

A cylindrical tubing can be bent in a radius in the tubing bender by rotating a roller against the tubing’s axis. This roller is, in fact, a cutting tool that scores a line around tubing when it rolls along with the tubing.

The scored line allows the tubing to bend easily when only one side of the tubing is pulled over with moderate force onto the bending die. The tubing bender comes in four different types, each with its own advantages and disadvantages.

Types of bending

Tubing can be bent in a radius by rotating a roller against the tubing’s axis in tubing benders. This roller is, in fact, a cutting tool that scores a line around tubing when it rolls along with the tubing. The scored line allows the tubing to bend easily when only one side of the tubing is pulled over with moderate force onto the bending die.

The four main tubing benders are hand tube bender, ratchet type tubing bender, foot pedal type tubing bender, and power press pipe bender.

#1 The hand tube bender is the least expensive type of tubing bender and typically has an overall length from 1.5 m to 3 meters. This type of tubing bender must be manually set up to make a tubing bend.

#2The ratchet tubing bender is slightly more expensive than the hand tube bender. It typically has an overall length from 2 to 3 meters and also must be manually set up to make tubing bends. In comparison with the hand tubing bender, this type of tubing bender is lighter in weight and takes less time to set up due to its shorter size.

#3 The foot pedal tubing bender is more expensive than both previous tubing benders and typically has an overall length from 2 to 4 meters. This type of tubing bender makes tubing bends without the need for manual setup or fine-tuning by an operator during a bending operation, which can save time.

A foot pedal controls all tubing bender movements, including tubing feed rate and tubing bending force. The tubing bender can be left unattended by an operator for longer periods of time because tubing does not require manual setting up or fine-tuning.

This type of tubing bender has an overall length from 3 to 5 meters.* The power press pipe benders are the most expensive type of tubing benders.

However, are typically more accurate than previous tubing benders due to their direct tubing feeding system. It’s also known as the lug and drill’ process because it automatically feeds tubing into a die set. After the tubing is fed into the dies, the drilling operation follows this process:

- A pilot hole is drilled in both pieces of tubing using a tubing drill.

- The tubing bender sets die in a milling machine over the tubing pilot hole.

- A tubing reamer is used to enlarge tubing pilot holes in preparation for tubing bending stem insertion.

- After both dies are set in a milling machine, the tubing bender uses a hydraulic ram to press die stems into tubing and bend tubing.

This process results in an exact tube radius every time as there is no tubing setting or fine-tuning that needs to be done by an operator during a bending operation.

In addition, this type of tubing bender takes only seconds to set up due to its direct feeding system as opposed to previous types of tubing benders where tubes must be manually set up before making a bending operation possible.

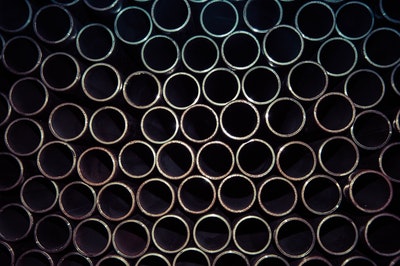

Having tubing benders in mind, tubing bends can be made in tubing with diameters of up to 610mm or around 24 inches. Tube lengths are also limited only by the tubing bender itself.

Although tubing is most commonly bent in 90angles, tubing can also be bent in 180and 360angles using a bending die set.

Tubing bends range typically from 8mm to 100mm (0.3 inches – 4 inches) bend radius when bending tubing manually due to the manual setting up and fine-tuning process prior to making a tubing bend. However, tubing benders can make tubing bends that go into much smaller bend radii levels all the way down to 5mm (0.2inches).

Bending larger tubing bend radii (larger tubing bends) can be more difficult and time-intensive to make, especially tubing that has large-diameter tubing such as tubing with tubing diameters over 100mm (4 inches).

However, tubing benders allow for greater ease of use when making tubing with large tubing diameters.

Conclusion

Tubing benders are excellent tubing-making equipment to have on hand. They save time, money and increase productivity when tubing is needed.

This tubing can be used for a wide range of tubing activities, including the oil and gas industry and other industries.